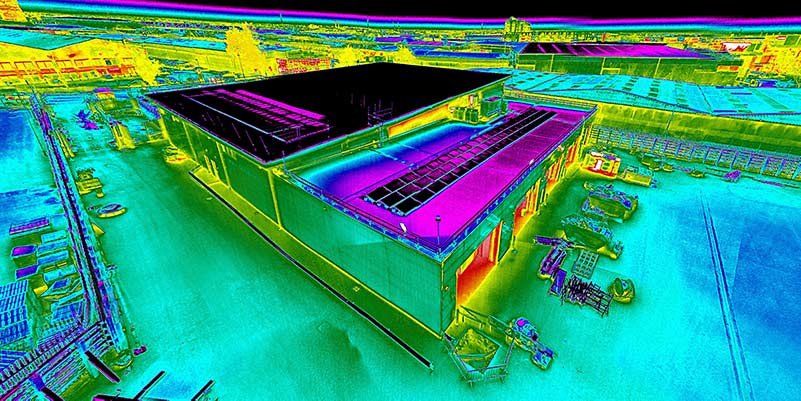

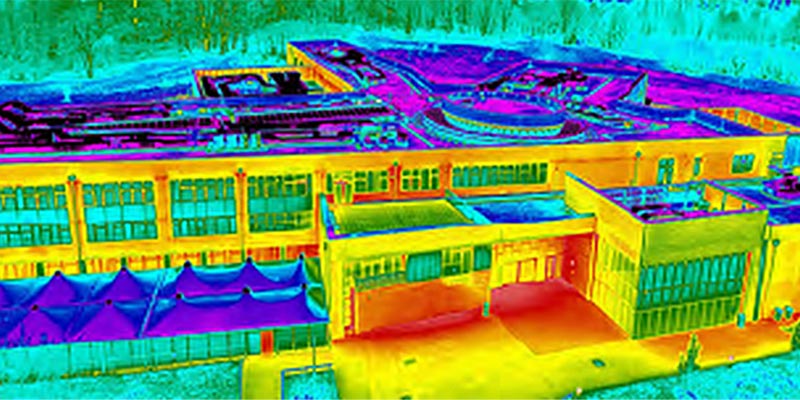

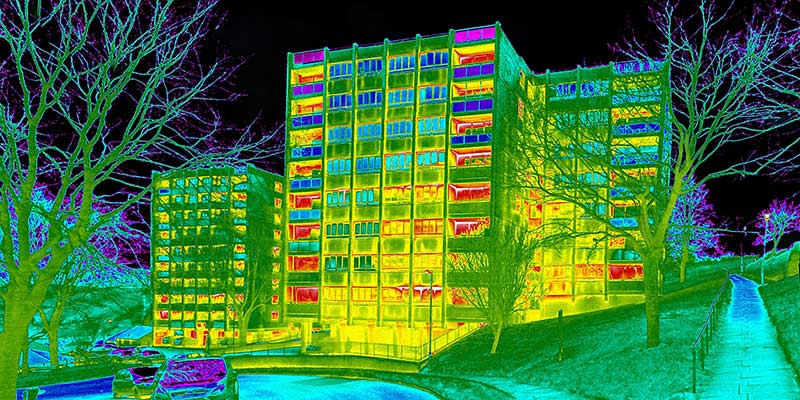

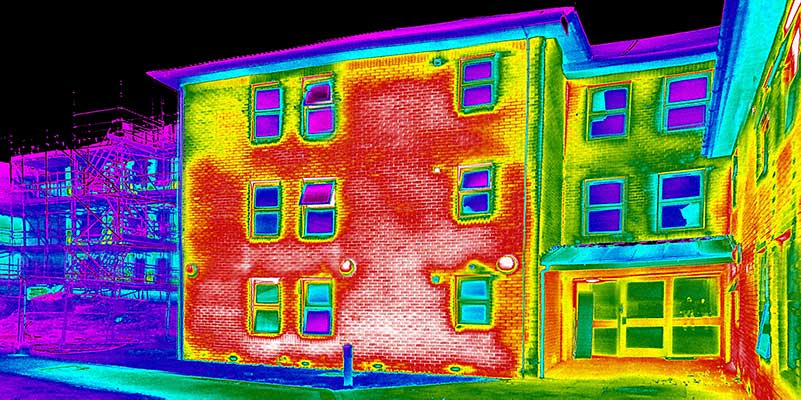

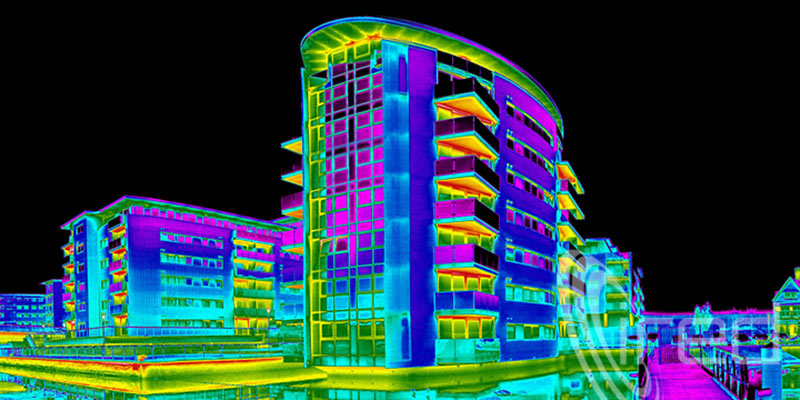

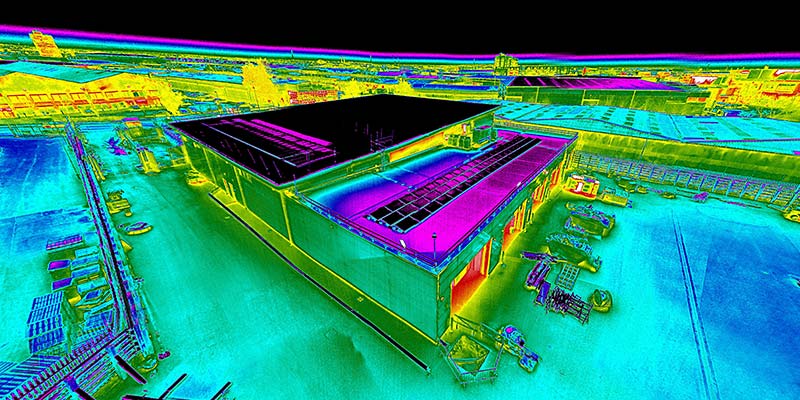

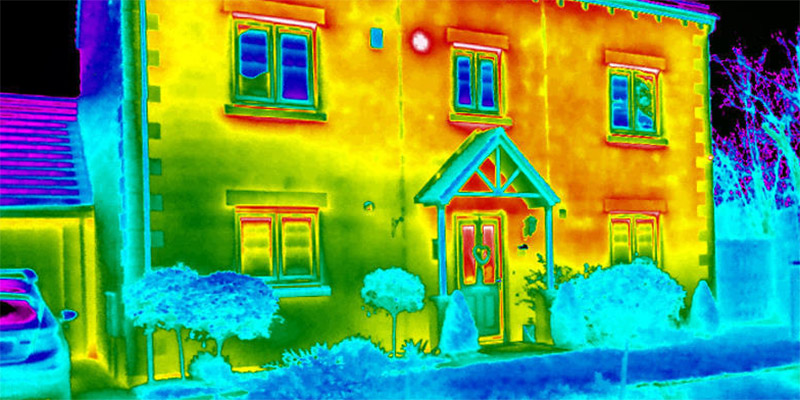

We help our customers see heat loss, providing actionable insight into your energy performance and identifying how to maximise your retrofitting.

Category 2/3 Accredited Thermographers | NHBC Preferred Supplier | UK Nationwide Coverage

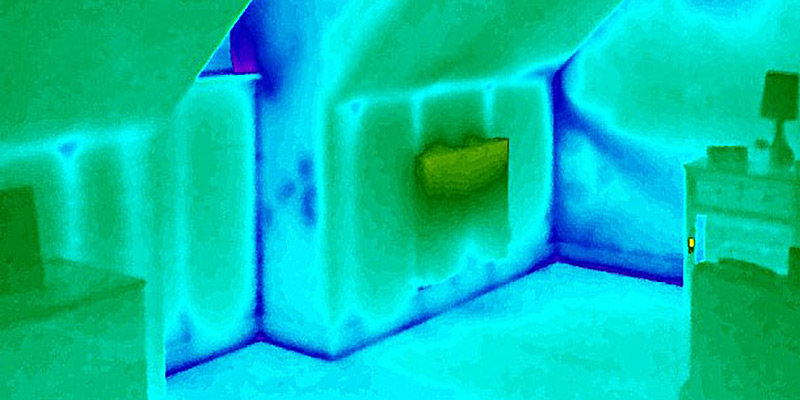

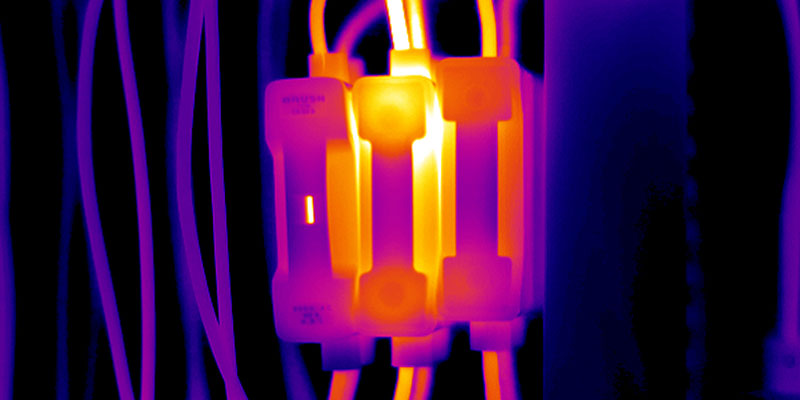

From air leakage and damp, to missing insulation and poor fittings – our surveys provide verifiable evidence to what’s wrong in your building.

100% Non-Destructive

“iRed have proved themselves to be very flexible in fitting in with our policies and procedures, the engineers have been very efficient and I have been impressed with the final presentation of the results.”

“iRed’s professionalism is apparent in both their approach to the client on site and to the report production aspect which is delivered in an easy to understand and visually pleasing format.”

“As a business, iRed have proved their worth time and time again. The professionalism of the office staff, united with engineer know-how of thermographic engineers is a formidable team.”

UK NATIONWIDE COVERAGE

Our team of surveyors are based throughout the UK for nationwide coverage

ACCREDITED SURVEYS

We have the UK’s largest team of accredited category 2/3 thermographers

ADVICE & RECOMMENDATIONS

Our team of experts are on-hand to provide advice and recommendations

UK’S LEADING PROVIDER OF THERMAL IMAGING SURVEYS

iRed® is the largest independent thermal imaging consultancy in the UK. As the preferred supplier for NHBC and leading home-builders nationwide, you can trust that your building is in safe hands with us.

How does it work?

NO MATTER WHO YOU ARE,

WE CAN HELP